D-Series

The sturdy D series, designed for non-tillage cultivation, has been updated significantly for the 2021 season. Coulter pressure is now controlled hydraulically from the cab, and each coulter has its own pressure cylinder. The ingenious active hydraulic system only requires 5 l/min of continuous flow from one manifold block. It adjusts coulter pressure whenever the coulters ride over a rock or sink into a hollow, maintaining the set pressure on each coulter, which ranges between 60 kg and 220 kg. Coulter lubrication has also been improved, and the nipples can now be found in centralised locations above each coulter. The D series also includes all the new features that have been introduced in the rest of the range in autumn 2020:

- The land wheel has grown with its redesign, achieving reduced slippage and greater sowing precision. The power transmission from the land wheel to the gear box has also been strengthened.

- Maintenance of the roller wheels has been made easier with a centralised lubrication system, which comes as standard with 7.5x20" roller wheels.

- Steps have been added in each corner inside the hopper to make movement easier, and the remaining seed quantity can be easily checked using the handy scale sticker. Hopper cameras are also available as an optional extra.

- An extension is also available for the hopper's partition wall for organic growers. This allows the partition wall to be placed fully forward to maximise the volume inside the hopper.

- The ISOBUS controller has been updated and its user-friendliness has been further improved. A handy row marker lifting feature for clearing poles is included as a new feature.

- The larger Plus hopper has stylish LED lighting as standard.

- The updated 1-row s-tine cultivator and front-mounted tined weeder are now available as optional extras.

The coulters of D series drills are always of the Combi type, meaning that seeds and fertilizer are deposited in the same row with a row spacing of 16.7 cm. Drills are available in 3-metre and 4-metre variants.

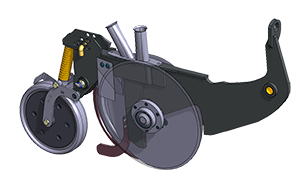

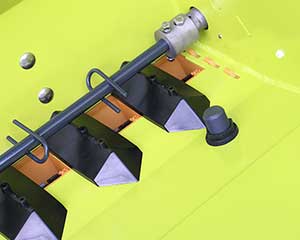

The D series' double-disc coulter design is intended specifically for non-tillage cultivation but is also suitable for cultivated soil. The coulters are quite far apart due to the 16.7 cm row spacing. Thanks to the 445 mm diameter discs made of abrasion-resistant steel, the drill does not require much traction power and is very effective at cutting through plant debris. At 60–220 kg, the series' coulter pressure range is the broadest on the market in its size class. The depth control wheels situated next to the coulters ensure that the coulters hold their set sowing depth precisely at the point where the seed is sown. The placement of seeds in the furrow is ensured with a separate guide lip. A spring-loaded closing wheel closes the seed furrow and ensures good sowing results.

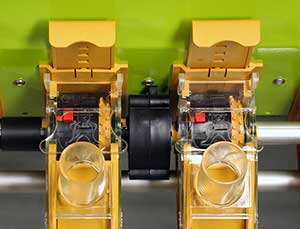

The combi drill is powered by the land wheel, from which power is transferred via a continuously variable transmission to the feeding mechanism. Feed quantities can be set as desired precisely from small quantities of small seeds to large quantities of large seeds. The feed is reliable in all conditions, even without electricity from the tractor.

Reliability and simplicity are the focus of the feed mechanism's design. The entirety of the feed roller's width is always used, precisely maintaining even small feed quantities at all drive speeds. A separate small feed roller is used when sowing small seeds, allowing for precise feed quantities of just a few kilograms. Calibration is very easy to perform and adjustments can be made with a remote controller for fertilizer and seeds, available as an optional extra.

We offer a wide variety of controllers. The simplest form available is a surface area meter or a G-Wizard or ISOBUS controller. The use of precision farming applications is possible, as adjustments to fertilizer and seed quantities can be done electronically via the controller.

In addition to the options mentioned above, there are a number of other extras available, including various towing solutions, front cultivators, row markers, spraying band switches, hopper level sensors, seed sieves, half lift functionality and small seed and starter extras.

Coulters

The double-disc coulter of the D series is the product of an extensive research and development process and is intended for non-tillage cultivation but can also be used on a cultivated surface. The double-disc coulters are suspended by a support wheel located next to the coulters that ensures that the coulters follow the shape of the surface exactly and preserves the set sowing depth. A separate guide lip ensures that the seeds are deposited at the bottom of the seed furrow, and the closing wheel located behind the coulter makes certain that the narrow furrow is closed. As a new feature, coulter pressure is now controlled by an ingenious active hydraulic system and can be easily adjusted from the cab. Additionally, lubrication points have been moved to an easier location on top of the coulter shaft. The drill's row spacing is 16.7 cm and coulter pressure is 60–220 kg.

Hopper

All models use Plus hoppers: 4,200 l on 3-metre models and 5,700 l on 4-metre models. The hoppers have an adjustable partition wall, for which an extension is available as an optional extra for organic growers. All hopper models have a simple, easy-to-use cover with a quick release latch. The cover can be opened both ways or up to the partition. Hoppers are equipped with fertilizer sieves as standard and seed sieves are available as an optional extra. All hoppers can be equipped with small seed and starter extras at the factory or retroactively. A camera system is also available. Seed hoppers are equipped with a new, handy level scale that can be used to see the quantity of seed left in the hopper. Sturdy self-cleaning working platforms, railings and steps have been designed to make access and work tasks safe.

Controllers

We offer a wide variety of controllers. The simplest form available is an electronic surface area meter that has two surface area calculators with the basic controller. G-Wizard's graphical controller offers access to most of the functions associated with managing and monitoring the combi drill. All the necessary information is displayed in real time and can be seen at a glance on the screen. Depending on the options installed on the drill, features such as monitoring of driving speed and data from two surface area calculators, hopper level sensors, axel rotation sensors and the gearbox, control of row markers, spraying bands and the half lift function as well as remote fertilizer control (G-Wizard Plus) are available.

The updated ISOBUS controller makes it possible to control the combi drill from the tractor's own ISOBUS controller. A separate ISOBUS controller installed in the tractor is also available. The ISOBUS controller enables you to adjust fertilizer and seed quantities while driving and make use of precision farming applications, allowing for adjustments to be made based on location information. Features such as monitoring of driving speed and data from three surface area calculators, hopper level sensors, axel rotation sensors and the gearbox, control of row markers, spraying bands, the half lift function and the row marker lifting feature for clearing poles as well as remote fertilizer and seed control are available.

Roller wheels

The wheels situated behind the coulters act as both the travel and roller wheels of the drill. This removes the need for separate rolling after the crops have been sowed. Drills are always fitted with large-diameter tractor-pattern 7.5x20" wheels. As a new feature, all drills are now equipped with a centralised lubrication system for bearings, and brakes are now available as extras. Large tyre sizes are particularly useful on lighter soil types, as the drill becomes lighter to tow and the risk of bulldozing is reduced. Larger tyre sizes also reduce fuel costs and cause less damage to soil structure, thanks to lower surface pressure.

The wheels also allow for the drill to be towed between locations with a full hopper and provide a strong and open design. Locations that may need maintenance are easy to reach. Thanks to the bogey construction, the wheels follow the shape of the terrain very closely, the rows stay uniform and the drill remains steady while it is being towed from one location to another.

The following harrow comes as standard and harrows between the rows, breaking up the soil packed by the drill's tyres. The harrowed layer of soil prevents the surface from silting and a crust from forming as well as slowing evaporation of moisture from the soil. The half lift function, which is available as an optional extra, ensures the harrow remains in contact with the ground while the tractor and drill turn around on the headland.

Accessories

A wide variety of different optional extras are available for D series drills. Various towing solutions are available, such as towbars and packers. The cultivator selection includes a tined weeder, 1-row and 2-row levellers, s-tine cultivators and a disc cultivator. Row markers, spraying bands, half lift functionality, hopper level sensors, seed sieves and small seed and starter extras are also available.

Hydraulic row marker

Hydraulic row marker

Disc cultivator

Disc cultivator

1-row leveller

1-row leveller

2-row leveller

2-row leveller

2-row s-tine cultivator

2-row s-tine cultivator

Small seed box

Small seed box

Half lift functionality

Half lift functionality

Seed-side spraying band switches

Seed-side spraying band switches

Fertilizer-side spraying band switches

Fertilizer-side spraying band switches

Fertilizer and/or seed remote control

Fertilizer and/or seed remote control

Seed sieves

Seed sieves

Improved hopper monitoring

Improved hopper monitoring

Drawbar

Drawbar

Packer

Packer

Precision farming application

Precision farming application

Technical specifications

| VANTAISTO | D300 | D400 |

| Soil preparation | Direct seeding, lightly tilled, tilled | Direct seeding, lightly tilled, tilled |

| Coulter type | double disc | double disc |

| Depth control | Depth control wheel | Depth control wheel |

| Coulter durability | Excellent | Excellent |

| Coulter pressure range | 60-220 kg | 60-220 kg |

| Coulter pressure adjustment | Hydraulic | Hydraulic |

| Pressure element | Hydraulic cylinder | Hydraulic cylinder |

| Seed coulters, pcs | 18 | 24 |

| Row spacing, seed | 16,7 cm | 16,7 cm |

| Fertilizer placement | seed coulter | seed coulter |

| S-tine fertilizer coulter | - | - |

| Fertilizer disc coulter | - | - |

| Fertilizer double disc coulter | - | - |

| HOPPER | D300 | D400 |

| Options | Plus | Plus |

| Capacity | 300 Plus 4 200 l | 400 Plus 5 700 l |

| Partition wall | Adjustable | Adjustable |

| Sieves for fertilizer | Standard | Standard |

| Sieves for seed | Option | Option |

| Tarpaulin cover | Manual rollin/spring operated (Plus) | Manual rollin/spring operated (Plus) |

| Metering device, fertilizer | Rifle feed, gearbox adjustment | Rifle feed, gearbox adjustment |

| Metering device, seed | 2 studded wheels, gearbox adjustment | 2 studded wheels, gearbox adjustment |

| Small seed box | Option | Option |

| PAcker wheels | d300 | d400 |

| Tyre options | 7.5 - 20" | 7.5 - 20" |

| Brakes | Option for 7.5-20 | Option for 7.5-20 |

| draw equipment | d300 | d400 |

| Hydraulic track marker | Option | Option |

| Packer 100 cm/7.5x16" | - | - |

| Packer 140 cm/10.0/75-15.3 | Option | Option |

| control unit | d300 | d400 |

| Options |

No control unit/Area metering/ G-wizard/ISOBUS |

No control unit/Area metering/ G-wizard/ISOBUS |

| Tramlines for fertilizer | Option | Option |

| Tramlines for seed | Option | Option |

| Fertilizer remote control | Option | Option |

| Seed remote control | Option | Option |

| Precision farming solution | Option | Option |

| Intensified hopper monitoring | Option | Option |

| options | d300 | d400 |

| Track marker, hydraulic | Option | Option |

| Single-row front leveller | Option | Option |

| Double-row front leveller | Option | - |

| Double-row s-tine leveller | Option | - |

| Disc cultivator | Option- | - |

| Half lift | Option | Option |

| Small seed and start fertilizer device | Option | Option |

| dimensions | d300 | d400 |

| Working width, cm | 300 cm | 400 cm |

| Transport width, cm | 300 cm | 400 cm |

| Transport height, cm (Eco/Plus) | 302 cm | 352 cm |

| Working height, cm (Eco/Plus) | 205 cm | 233 cm |

| Lenght, cm | 591 cm | 851 cm |

| Weight, cm | min 4500 kg | min 6100 kg |

| Power demand, kWh | 60+ kW | 85+ kW |